Understanding DTF Transfer: The Future of Custom Printing

- Admin MetaStyle

- Nov 20, 2024

- 1 min read

Updated: Nov 25, 2024

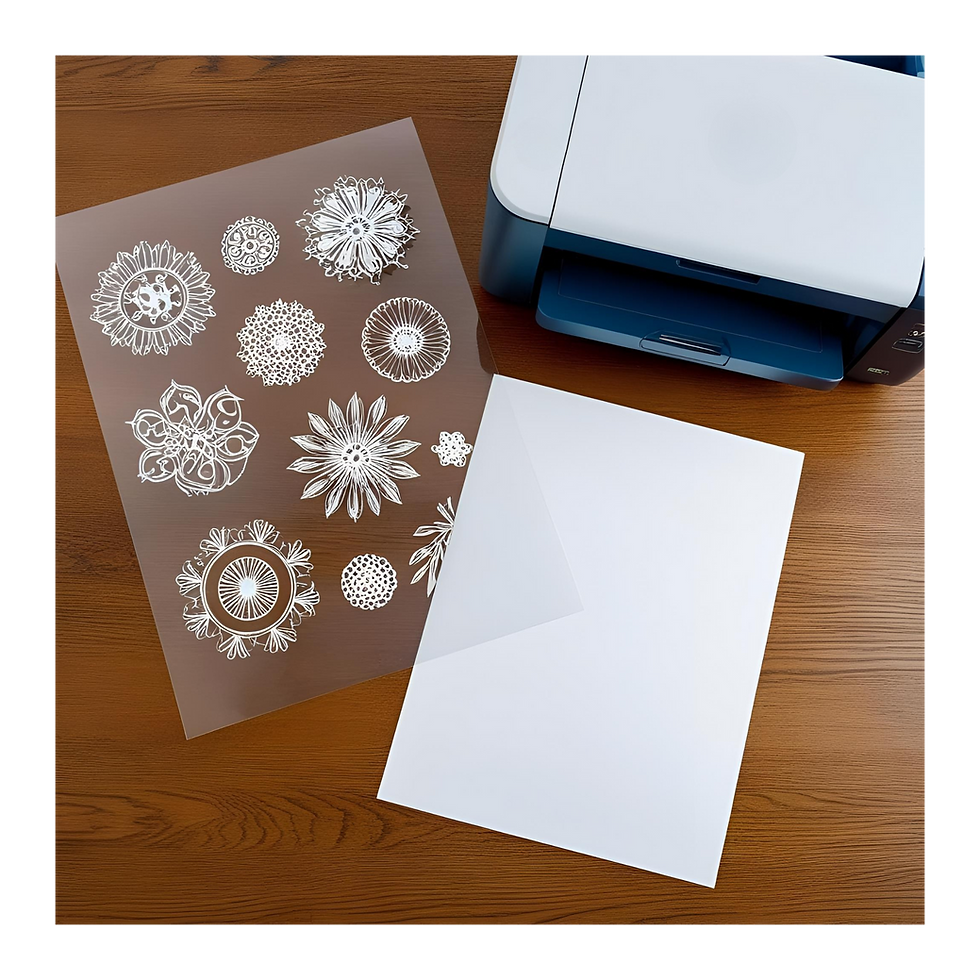

Direct-to-film (DTF) transfers are revolutionizing the custom printing industry with their versatility, durability, and ease of use. Whether you're a business owner, a hobbyist, or someone exploring new creative outlets, DTF printing is worth your attention.

How Does DTF Transfer Work?

Design: Create your design using graphic software.

Printing on Film: A specialized printer prints the design on a DTF film with CMYK DTF ink first. White DTF ink is added last to ensure opacity.

Powder Application: A layer of adhesive DTF powder is applied to the wet ink to help the design adhere to the fabric later.

Heat Curing: The powder-coated film is heated to cure the adhesive.

Transfer to Fabric: Using a heat press, to transfer the film on the fabric. Once the film is peeled off, leaving the design intact.

Advantages of DTF Transfers

Versatility: Works on a variety of materials, including cotton, polyester, and blends.

Durability: DTF prints are resistant to washing and wear, ensuring long-lasting designs.

High Detail: Ideal for fine designs and vibrant colors.

No Pre-Treatment Needed: Unlike DTG, DTF doesn’t require fabric pre-treatment, saving time and effort.

Tips for Success with DTF Transfers

Use high-quality DTF films and DTF adhesive powders for the best results.

Maintain your printer regularly to avoid clogs and ensure vibrant prints.

Experiment with heat press settings to find the ideal combination for your materials.

Conclusion

DTF transfer printing is a game-changer in the custom printing world. Its flexibility, durability, and cost-effectiveness make it an excellent choice for anyone looking to create high-quality printed products.

Comments